30 YEARS OF EXPERIENCE

In Hull, Machinery and Cargo Surveys.

+500 Satisfied Costumers

Main Services

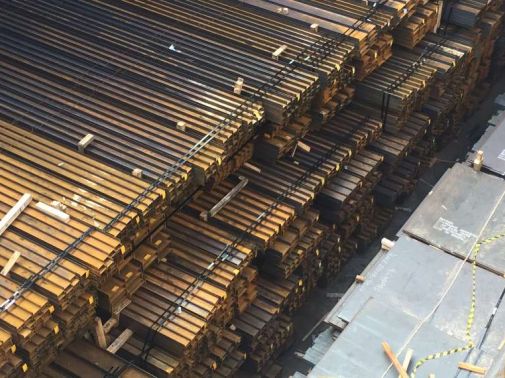

Loading Survey

A loading survey ensures that cargo is loaded safely and according to the ship's capacity. It verifies that the weight and distribution of the cargo won't affect the ship's stability during the voyage.

ON/OFF Hire Bunker & Condition Survey

This survey is done when a ship is rented (hired) or returned (off-hired). It checks the ship's fuel levels (bunkers) and overall condition to determine any damages or changes during the rental period.

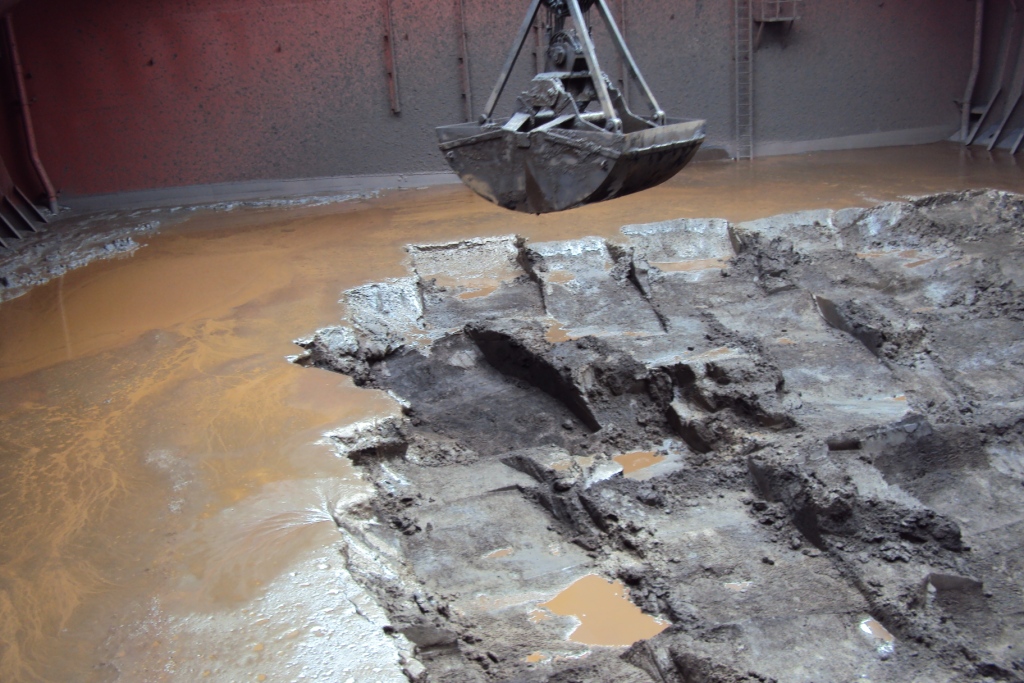

Iron ore loadings

This process involves loading iron ore onto ships, ensuring the cargo is properly loaded and evenly distributed to maintain the ship's balance and safety.

Holds Cleanliness Survey

Before loading cargo, this survey checks that the ship's holds (cargo spaces) are clean and free from contamination that could damage the cargo or violate regulations.

Draft Survey

A draft survey measures the ship's waterline before and after loading to calculate the weight of the cargo on board. It's a key method for verifying cargo quantity.

Bunker Quantity Survey

This survey measures the amount of fuel (bunkers) on a ship to ensure accurate fuel usage and billing. It’s commonly done during chartering or refueling.

SEATECH MARINE & CARGO SURVEYS

Seatech Marine & Cargo Surveys was founded in 1993, at Vitória, Espírito Santo, Brazil with the purpose of performing high quality services and attending exactly the specific needs of the clients with a reasonable and compatible price.

Seatech attends a wide range of services

being the Pre-loading (steel products / iron ore / fertilizers / grains), On/Off-Hire Bunkers and Conditions, Bunker Quantity, Hold’s Grain Cleanliness Condition and Draft the most requested surveys.

Strategically based in Vitória

Seatech can reach the ports of Tubarão, Praia Mole and Vitória within few minutes. Seatech owns four cars and a modern facility with first line equipment including computers, cameras and operative system, in order to well attend the services and in a quick and professional way.

Seatech also performs surveys all over the Brazilian territory.

Such as Acu Port, Santos, Rio de Janeiro, Itaguaí, Pecém, Suape, Barcarena, Vila do Conde, Itaqui, Manaus, Belém, Aratu, Paranagua, Rio Grande, São Francisco do Sul, etc.

Our staff is composed by qualified professionals with years of experience in the maritime market.

Certifications and Awards

Areas Attended

SEATECH operates at all Brazilian ports and select international locations, including the USA, Costa Rica, Argentina, Colombia, Peru, Ecuador, Mexico, Panama, Jamaica, Bahamas, and Chile. SEATECH provides survey services using its own staff or reliable local inspectors as needed.

Talk to us.

Our contacts always at your disposal

manager@seatech.eng.br

Skype

seatech.brazil

Engr. Rafael Azevedo

+55 27 99644.0750 (24hrs)

Engr. Daniel Azevedo

+55 27 99805.2664 (24hrs)